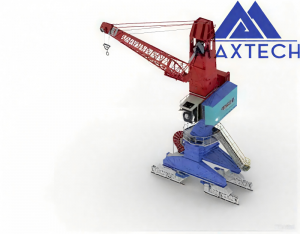

Rail Moving Crane Stiff Boom Crane Mobile Harbour with steel wire luffing

With profound expertise in the design and manufacture of rail moving crane, MAXTECH is able to meet the special needs of customers. We develop tailor-made crane installations, which meet the individual requirements profile.

Maxtech supply range : lifting capacity from 1ton to 100tons , the working radius from 5meter to 50meters .

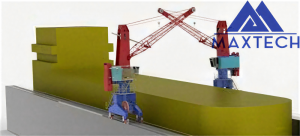

MAXTECH rail moving crane is a great choice when it comes to safe, fast, and flexible material handling and unloading. Like for ship building and repair.

a.Plain and pure architecture based on a pedestal slewing design with cylinders;

b.Maxtech rail moving cranes are exceptionally low in maintenance;

c.Combining minimum complexity and optimised weight with high-quality components;

d.Special features such as special corrosion treatment;

e.MaxTech Marine crane is a solid and reliable asset for every working environment.

Send us the enquiry to customize your crane , we gonna offer you a free quotation .

More Features for MAXTECH Crane(Rail Mving Crane );

① Hoisting capacity up to 100 metric tons

② Boom/Jib working radius up to 50 meters

③ Matched with container spreader and grabs for handling containers and cargo.

④ Long-life surface treatment: corrosion protection

⑤ Integrated electro hydraulic drive / HPU

⑥ Stainless Steel pipes for hydraulic system

⑦ Continuous slewing

⑧ Low / high temperature operations

⑨ Anti-collision system

⑩ Remote control / operator’s cabin

⑪ Overload protection systems: MOPS & AOPS;

⑫ External hydraulic power packs

⑬ Spray metalizing

⑭ Crane certification according to selected rules and regulations

⑮ Explosive -protection design ATEX Zone 1 and 2 execution

⑯ Tugger winches

Manufacturing Standards

The product is designed and manufactured in strict accordance with the latest effective specifications of the classification society at the time of contract signing to ensure that the product quality meets industry standards.

Classification Societies: BV, CCS , ABS, KR, LR , RAIN, DNV, et.

Testing and Certification

Before leaving the factory, the equipment needs to undergo strict tests, including performance tests (lifting, luffing, and slewing movements with rated and overload loads), emergency stop confirmation, manual brake release tests, limit switch confirmation (under no - load conditions), and insulation resistance measurement. The test records of each item will be submitted to users to ensure reliable product performance.

Industry Certifications

We have established cooperative relationships with several renowned enterprises that hold leading positions in their respective fields.